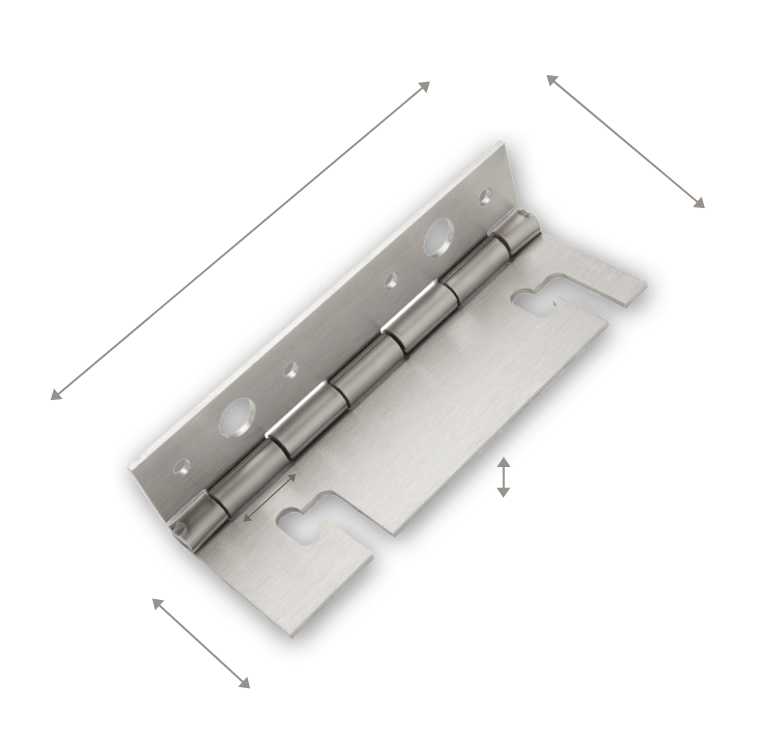

A hinge is never just a hinge. There is a great variety in shape, thickness, material, processing and finishing. All with their own specific advantages. In addition, a hinge also consists of different parts, which may have different properties depending on the purpose of your project.

That is why we have listed the most important technical terms for the hinge for you. This way you know exactly where you stand in an advice.

The hinge knuckle is the circular part. Also called bead or loop. The knuckles of the two different clasps usually alternate around the pen.

1 of 10 PinThe pin connects the two (or more) hinge leafs.

2 of 10The pin diameter determines the thickness of the pin, measured in diameter.

3 of 10 LeafThe leaf or blade of the hinge is the rotating or fixed part of a hinge.

4 of 10The leaf width is the distance from the end of the leaf to the center of the pin.

5 of 10The leaf thickness is the thickness of the hinge.

6 of 10The hinge width is the total width of the open hinge: measured at right angles to the pin.

7 of 10The knuckle length is the length from one end to the other end of a single knuckle, parallel to the pin. Usually this is a fixed size, e.g. 30mm, 25mm, 20mm, etc.

8 of 10The end play is the light axial movement between the knots over the axis of the pen. This is caused by the small space between the nodes, which causes the leaf to hinge.

9 of 10The hinge length is the total length of the hinge measured over the leaf parallel to the pin.

10 of 10To help you on your way, we would also like to give you some verbs that are useful when discussing, among other things, the different operations of the hinge.

| edge breaking | also known as 'chamfering': this removes the sharp edge of the leaf. |

| brushing | The hinge has a ground appearance with a light grinding structure. This is an optical something that combines nicely with for example the design where it is applied. |

| bending | make a small nod behind the knuckle. Sometimes this is required to be able to apply the hinge perfectly because the parts to be hinged fit better this way. |

| grinding | equipped with a ground appearance with a grinding structure. |

| notching | The two outer nodes of the hinge have an indentation so that the pen cannot come out without permanently deforming the hinge. |

| clamping | Press the button in such a way that the pin will not come out after assembly. This is a lighter form than notching and is optically almost invisible. |

| riveting | machining the pin to form a spherical head at the end of the pin. In this way, the pen is stuck in it and it doesn't matter how you mount the hinge. Even when mounted with rivets, the pen will not come out without force. |

| welding | welding is used to make a permanent connection between 2 parts. For example because of extreme forces the knot is welded to the leaf. |

| ball polishing | in the case of stainless steel: the hinge has a smooth, slightly shiny surface. |

| sovereign hinge holes | A hole with a beveled edge so that a countersunk bolt or screw, for example, fits into it. |

At BOSCH Hinges we make everything to measure. So there is a lot possible for your hinge.

Want to know more about the possibilities? Send a message via the chat pop-up or call or email us for more information and advice.

Since 1929 BOSCH Hinges stands for the production of high quality metal hinges for industrial applications, with a specialism for customization. We meet the quality requirements according to the NEN and ISO 9001 TÜV Netherlands standards.

Since 1929 BOSCH Hinges stands for the production of high quality metal hinges for industrial applications, with a specialism for customization. We meet the quality requirements according to the NEN and ISO 9001 TÜV Netherlands standards.

BOSCH Scharnieren levert maatwerk scharnieren voor de industrie. Neem contact op voor een offerte of passend advies.

BOSCH Scharnieren levert enkel scharnieren voor industriële toepassingen. Aan particulieren wordt helaas niet geleverd.

BOSCH Scharnieren is de specialist in maatwerkscharnieren met korte levertijden. Stel uw offertevraag in het veld hieronder of deel uw werktekening en eventuele specificaties voor een offerte. Wij helpen u graag uw project realiseren.

BOSCH Scharnieren is de specialist in maatwerkscharnieren met korte levertijden. Stuur ons uw werktekening of ontwerp en eventuele specificaties voor een offerte. Wij helpen u graag uw project realiseren.

BOSCH Hinges supplies custom hinges for the industry. Please contact us for a quotation or appropriate advice.

BOSCH Hinges only supplies hinges for industrial applications. Unfortunately, we do not deliver to private individuals.

BOSCH Hinges is the specialist in customized industrial hinges with short delivery times. Send us your working drawing or contact us directly in the field below to discuss the possibilities. We are happy to help you realize your project.

BOSCH Scharnieren is de specialist in maatwerkscharnieren met korte levertijden. Stuur ons uw werktekening of ontwerp en eventuele specificaties voor een offerte. Wij helpen u graag uw project realiseren.

Do you need a custom hinge for your (industrial) project? You imagine it, we make it. With fast delivery times as well. Send us your work drawing or contact us directly to discuss the possibilities. We will gladly help you realize your idea.

Prefer to call us? +31 (0)314 369988

Prefer to look around? View examples of custom hinges.